I phone 14 print limitation

Most people who use UV Printer say, “It’s not easy to print the phone case because of the height of the iPhone 14 camera.”

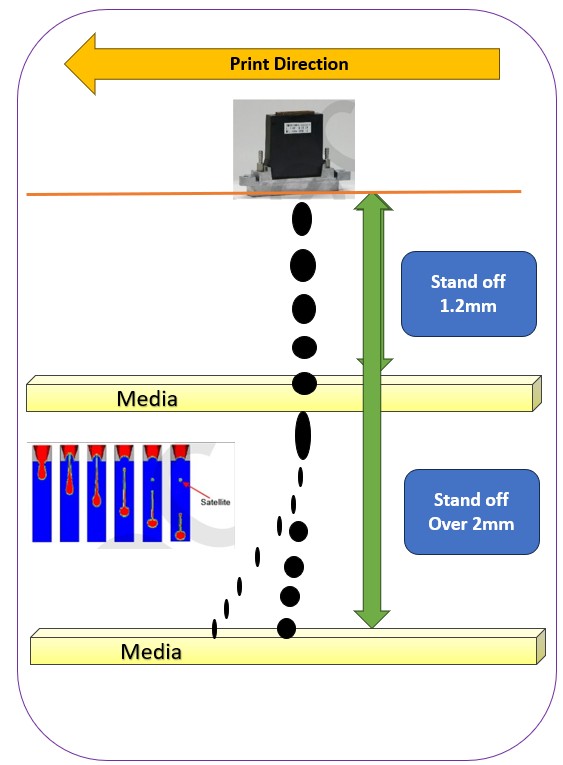

If the gap between the print head and the material is large, I will explain why the ink falls around the material.

I. In conclusion _I phone 14 print limitation

The optimal gap between the material and the print head, i.e. stand off, is 1.2mm.

There is no significant change up to 1.5mm, but as the stand off increases, the falling point of the jetting ink becomes unstable.

The part of the I phone 14 cell phone case is raised to the height of the camera, and to print with a UV printer, the stand off must be set high.

When printing with the stand off raised like this,

- Ink may bleed sideways, especially when the print volume is large and the pigment is heavy, such as white.

- Ink cannot fall into place for both white and color, so lines may appear on the white and the color may also appear rough.

- If the stand off exceeds the print head limit, the ink landing point will fall somewhere else due to air vortex.

- If you print for a long time with a high stand off, the print head nozzle may become partially clogged.

What print head do you use? Possibility is determined depending on

Even if it is possible, the print quality will obviously deteriorate and the defect rate will also increase.

When repeating the same task for a long time, the print head nozzle may be partially blocked.

II. Print head’s Stand off _I phone 14 print limitation

1. In most cases, it is not specified in the head specifications. _I phone 14 print limitation

Inkjet board and SW manufacturers or equipment manufacturers receive print head manuals from print head companies. They contain technical information on mechanisms, electrical, waveforms, etc., but usually do not contain information on standoff.

The reason is,

Each printer manufacturer uses different inks, and the waveform changes depending on the ink, and the standoff can be higher or lower depending on the waveform. That is, it seems that it is not specified because it can vary.

The waveform must be properly matched like this to achieve the optimal ink jetting condition at a standoff of 1.2 mm, and

No matter how well the waveform is matched, the standoff will not be significantly higher.

2. Xaar1201 Print head stand off

This is a print head manufactured by Xaar, a British company, as an OEM for Ricoh. It was discontinued 4 years ago for some unknown reason.

Ricoh is still producing it in small quantities, and it is generally called Gen5i.

The official name from Ricoh is TH5241.

Ricoh’s print head specifications do not include stand off, but Xaar’s brochure does indicate stand off.

Wait, let’s look at the important details:

[Up to 3mm is supported, but 1.33mm is optimal. If the gap is large, drop position errors may occur and image quality may deteriorate.]

3. Xaar1201 Print head 2 years experience _I phone 14 print limitation

A long time ago, I ran several samples while operating it as a demo device for 2 years.

There were samples that were run with the standoff raised by more than 5mm, and I printed several times with good results by applying a different waveform built into the UV Printer.

Some time later, although the nozzle condition was good, banding that looked like lines occurred on the printed material.

I don’t know the cause, but it seems that the waveform applied when printing at a high position put a strain on the print head.

There are print heads that can print with a high standoff,

but even if there are, since they have to apply a rough waveform, unpredictable problems can occur.

Four years ago, Xaar discontinued the print head, and since then, we have also stopped selling UV printers equipped with the Xaar1201 print head.

Recently, I heard that

the price of the Gen5i print head has risen to 3.5 million won, and although it is a print head that implements good print quality, Ricoh seems not to be actively supplying it. As mentioned above, unpredictable issues arise, so it seems like they are only doing the bare minimum to respond.

III. If the ink does not fall into place,,, _I phone 14 print limitation

1. Why ink doesn’t fall into place _I phone 14 print limitation

Even if ink is fired under good jetting conditions, as shown in the photo below,

The farther away the ink falls, the less likely it is that the ink will fall into place.

The speed at which ink falls is usually 7 m/s, or 7 meters per second. Ink jets very quickly.

However, this is the speed at which it is first jetted through the nozzle,

The further away the point of ink deposition is,

* The speed of low-mass ink droplets decreases with distance from the first 7 m/s,

* The offset values set to the falling ink drop speed of 7m/s and the print head carriage transfer speed of 0.8m/s also do not match.

* In the end, the ink droplets miss and fall where they should, so the print quality naturally becomes rough.

And, as the falling distance increases,

* The ink jetting speed decreases rapidly, or the ink that fell as one unit breaks into small droplets.

* The speed also decreases, and the small mass of ink droplets split into several pieces is also affected by the air vortex generated by the print head carriage speed (0.8m/s).

* In particular, small mass ink droplets that are broken into several pieces fly along the print head carriage in air vortices and fall all at once in an unexpected location.

I think it will be easier to understand if you refer to the video. Just click here.

2. Dangers of Flying Splintered Ink Drops _I phone 14 print limitation

Small flying ink droplets fall on the bottom of the material, but also stick to the nozzle surface.

When one or two small droplets come together, they form a certain amount of large droplets.

The large droplets that form partially block the nozzle hole, preventing ink from spraying in a straight line.

In other words, it affects the printing quality by creating a banding that looks like a line by creating a diagonal spray.

The bigger problem is

If you do not properly wipe off the ink partially on the print head nozzle surface,

The ink around the nozzle may harden into a lamp and may not recover even after cleaning.

At first, the printing quality is affected by diagonal firing, and as ink accumulates and hardens in this state, it eventually clogs the corresponding nozzle.

Please refer to the photo below for partial or complete nozzle blockage.

In this state, the print head nozzle pattern photo is as follows.

3. The person who actually prints _I phone 14 print limitation

At first, he printed several using a zig, but the starting point for each case was slightly off due to the air vortex, so now he is doing one at a time.

Even now, when I occasionally talk to the CEO of the company,

“CEO, if possible, please look for other items besides the iPhone 14 case.”

And, I heard that some CEOs buy cases that can be reassembled by removing the iPhone 14 camera part.

When I talk to CEOs of various companies, I also heard that the printing quality is poor, but it is possible to print the iPhone 14 with Mimaki.

III. This is how ARTJET supports our customers.

One thing I feel while selling and maintaining ARTJET UV Printers for 5 years is that the next most important thing after product stability is Troubleshooting DATA.

All products have problems, whether they are actual equipment problems or consumer errors, and product stability is how easily and quickly you solve those problems.

Since words alone are not convincing, we are organizing all the troubleshooting DATA as follows,

ARTJET UV Printer

1. Printhead Problems and Solutions Total 10

ARTJET UV Printer Problems and Solution_Printhead Problems Summary

Additional issue and solution

The red color does not appear at first, then appears during printing, and then does not appear again

2. Ink Supply Problems and Solutions Total 17

ARTJET UV Printer Problems and Solutions_Ink Supply Problems Summary

Comprehensive application

Damper replacement time

The nozzle test is fine, but it seems that a certain color is not coming out during printing

Capping station block positioning to match the print head and captop

Can I ignore the ink alarm and use it?

UV Printer Monday Morning Routine

I tried white cleaning every day for a month

3. Mechanical problem and Solutions

1. How to align the print head in a straight line

2. There is a clicking noise from the X-axis

3. Banding problem in specific section

4. The Importance of Head Height in Bidirectional Printing

5. Problems that occur when the wiper height is high

6. When the cleaning belt screw is loose

7. When the capping fixing plate does not fit

8. How do I prepare the ARTJET electricity?

9.When Anti-crash becomes a jam in captop

10. Print head Anti crash system

4. Electron board and Software problem is hereunder.

1. The printer works but printing does not work

2. Resetting to default settings

3. Touch panel does not turn on

4. The printer is printing, but nothing is printed

5. Software closes when I just press the print button

6. Printing in the wrong place

7. Positioning misalignment in X-axis direction

8. How to make the Offset fine tune

9. Vertical offset is not correct only for the right section of white

10. Software turn off when click print button

5. Sai Flexi Rip software

1. Sai Flexi Rip _ How to make the Spot Color & several mistakes

2. Sai Flexi Rip _ Color is strange after applying Spot color

3. Sai Flexi Rip _ White is sticking out

4. Sai Flexi Rip _ Installation and Dongle Key Recognition Failure Measures

5. Sai Flexi Rip _ Dongle Key Recognition Failure

6. Sai Flexi Rip _ White lines appear when printing only color

7. Sai Flexi Rip _ Color Adjustment through Graph

8. Sai Flexi Rip _ Print size compensation

9. Sai Flexi Rip _ Ink Consumption Calculation

10. What is ICC profile & menu board UV Printing

11. Sai Flexi Rip _ Dongle Key recognition Failure from USB port

12. UV Printer difference between 4-color and 6-color

6. Problems and solutions from actual consumer sites

1. Paper that absorbs ink

2. White Motor Pump Does Not Turn

3. A line-like thing appears at the end of the white print surface

4.Can varnish banding be reduced?

5. Are there many problems with China’s UV Printer?

7. UV Printer Application

we are explaining not only UV printer problems and solutions, but also what products are produced with UV printers.

1. Braille printing

2. Flip the material and align it

3. 2.5D UV print

4. ARTJET UV Printer Application 6 _아크릴 본딩 장비

5. I phone 14 print limitation

6. Mask printing not recommend

7. Leather Cigarette Case UV Printing

8. Round soccer strategy board UV printing

9. Primer performance & limitation

10. UV Print & Laser crop mark cutting

11. Mobil case UV print profit

12. Screen vs Digital Comparison and UV Printing on Hand Sanitizer Cases

13. Bottle zig & print

14. Canvas UV Printing

15. Applying epoxy effect with varnish

16. Making a light frame with UV Printer & Laser cutter

17. UV Printer & Laser Cutting Equipment Button Name Tag Making

18. UV Printer & Laser Cutting Making a Cell Phone GripTok

19. Making an Acrylic Keychain with UV Printer & Laser Cutter

20. UV Print with Zig

21. How to make RD WORKS CCD camera cutting Video manual

22. Acrylic bonding equipment

23. All the steps to create UVDTF

24. UVDTF TEST Result on various material

25. ARTJET CW+C Print time & Ink Cost

26. Create a white shield with different images on the front and back of the keyring

27. Keyring Business Required Equipment and Investment Costs

29. Acrylic Lighting Goods

30. Ballpoint pen jig printing

31. Staining occurs when printing on coated leather

8. Bonus

1. ARTJET UV Printer Old Model Refurbished

2. UV Printer Laser Cutter Bonding Machine Which equipment should I buy first?

3. Considerations when choosing a UV printer

4. DTF Printer Price and Specification Survey

5. Acrylic Bonding Equipment Don’t Put It Off Anymore

6. China inkjet level now

7. Thoughts on KOSIGN 2024

8. ARTJET Delivery Preparation

9. ARTJET Setting Sequence

10. UV Printer History and Future Prediction 1

11. UV Printer History and Future Prediction 2

12. UV Printer History and Future Prediction 3

13. UV Printer History and Future Prediction 4

14. UV Printer History and Future Prediction 5

15. Are there many problems with China’s UV Printer?

16. UV Printer Small Text Meaning

17. Is the XP600 head okay

18. Roland UV Printer Summary

19. Mimaki UV Printer Summary

20. UV Printer Alibaba Direct Purchase Considerations

21. Things to consider when buying a used UV Printer

That’s it for today.