iPhone 14 Printing Limits ARTJET 2025

So far, UV printer-related issues, We’ve compiled

24 articles on ink supply issues,

9 articles on head basics,

12 articles on actual head issues and their solutions,

10 actual mechanical Machine Problems and Solutions.

12 Problems and Solutions of Electronic Boards and SW Actually Issued

11 Problems and Solutions: Sai Rip Installation and Basic Settings, Spot Color Creation, and More

For related information, click on the article to go to the link.

Now, I’m explaining about the products that can be made with a UV Printer.

Expressing gradients and three-dimensionality with white

Today, I’ll explain why printing on iPhone 14 cases isn’t easy due to the height of the camera.

I’ll explain why printing doesn’t work properly when the gap between the head and the material is too high.

I. Let me start with the conclusion _iPhone 14 Printing Limits ARTJET 2025

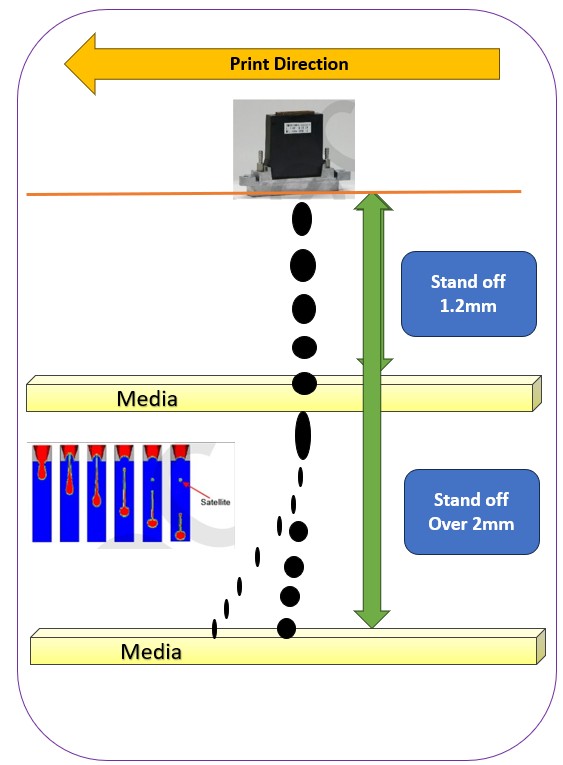

The gap between the printhead and the substrate is called “standoff,” and the optimal standoff value is 1.2mm.

Up to 1.5mm, there’s little change, but as the standoff increases, the ink that falls on the substrate will not fall in the correct location.

For printing with a UV printer, the standoff must be set high, as the iPhone 14 is the height of the phone’s camera.

However, if the standoff is high,

- ink will bleed sideways, especially with white ink, which has a high coating amount and heavy pigment content.

- Since neither white nor color ink falls in the correct location, streaks may appear on the white ink, and the color ink will appear rough.

- If the standoff exceeds the maximum value for the printhead, the ink will fall in a completely different location due to air turbulence.

- Printing for extended periods with a high standoff may also cause the printhead nozzle to become partially clogged.

Depending on the print head used, you may be able to produce a decent product, but print quality will significantly deteriorate and the defect rate will increase.

Repeated use of the same process over a long period of time can also partially clog the print head nozzles.

II. Print head Stand off _iPhone 14 Printing Limits ARTJET 2025

1. Why standoff is not indicated in the print head specifications _iPhone 14 Printing Limits ARTJET 2025

Inkjet board and software manufacturers, or equipment manufacturers, receive printhead manuals from printhead companies.

While these manuals contain technical information on the mechanism, electrical design, and waveform, they typically don’t include standoff.

This is because:

- Each printer manufacturer uses different inks,

- and the waveforms change depending on the ink,

- and the standoff can be higher or lower depending on the waveform.

- This means that standoff can vary depending on the ink used by each manufacturer, and therefore, head manuals don’t specify it.

On average, with a properly matched waveform, the optimal standoff is 1.2mm.

Of course, in some cases, it can be 1.5mm or 2.0mm, but even with a well-matched waveform, the standoff won’t be excessively high.

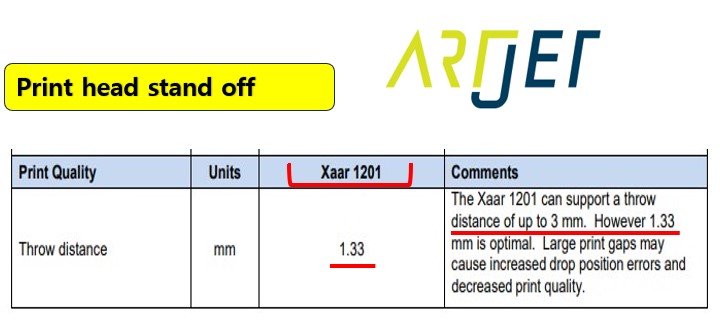

2. Xaar1201 Print head stand off _iPhone 14 Printing Limits ARTJET 2025

This print head was manufactured by Xaar, a UK company, as an OEM for Ricoh. It has now been discontinued for five years.

Ricoh continues to produce a small quantity of the same specs, generally referred to as the Gen5i.

The official Ricoh designation is TH5241.

While Ricoh’s print head specifications do not include standoff, Xaar’s brochure does.

Interpreting the underlined portion of the image above:

[Up to 3mm is supported, but 1.33mm is optimal. Larger gaps can result in significant drop position errors and poor image quality.]

3. 2 years of experience with Xaar1201 Print head _iPhone 14 Printing Limits ARTJET 2025

A long time ago, we ran several samples on a demo machine for two years.

We ran some samples with a standoff of over 5mm, and we successfully printed several successful prints using different waveforms built into the UV printer.

Shortly after, banding appeared on the prints, although the nozzles were in good condition.

The cause is unknown, but the waveform applied when printing at high altitudes appears to have strained the print head.

There are print heads that can print with a higher standoff, but even those that do require a more demanding waveform, which can lead to unpredictable problems.

Four years ago, Xaar discontinued their printhead, and since then, we have stopped selling UV printers equipped with the Xaar1201 printhead.

Recently, we’ve heard that

the price of the Gen5i printhead has risen to 3.5 million won, and despite its excellent print quality, Ricoh appears to be reluctant to supply it.

As mentioned above, unpredictable issues arise, so it seems like they are only doing the bare minimum to respond.

III. If the ink does not fall into the right place,,, _iPhone 14 Printing Limits ARTJET 2025

1. Why the ink doesn’t fall into place _I phone 14 Printing Limits ARTJET 2025

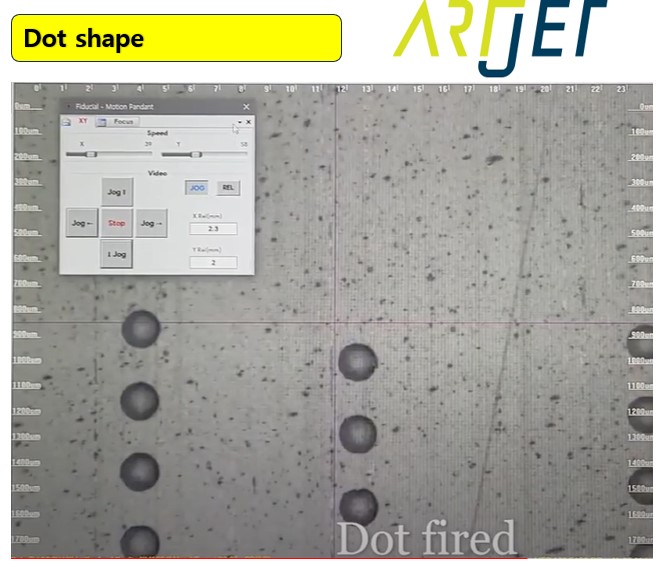

Even if the ink is fired under good jetting conditions as shown in the photo below, the greater the standoff, the less likely the ink will fall into place.

The ink droplet typically falls at a speed of 7 m/s, or 7 meters per second. The ink jets out very quickly.

However, this is the initial jetting speed through the nozzle.

- The velocity of the small ink droplets decreases over time from the initial 7 m/s.

- The offset value, which is adjusted to the 7 m/s droplet velocity and the 0.8 m/s print head carriage speed, also does not match.

- Ultimately, ink droplets miss their intended destination, resulting in poor print quality and inconsistent color reproduction.

As the drop distance increases,

- the ink jetting speed decreases dramatically, causing the ink, which had previously been clumped together, to break apart into smaller droplets.

- This decrease in speed also causes these smaller droplets to be affected by the air turbulence generated by the print head carriage speed (0.8 m/s).

- In particular, these smaller droplets, driven by the air turbulence, fly along the print head carriage, eventually landing in unexpected locations.

It might be easier to understand if you watch the video. Just click here.

2. The dangers of flying, split ink drops _iPhone 14 Printing Limits ARTJET 2025

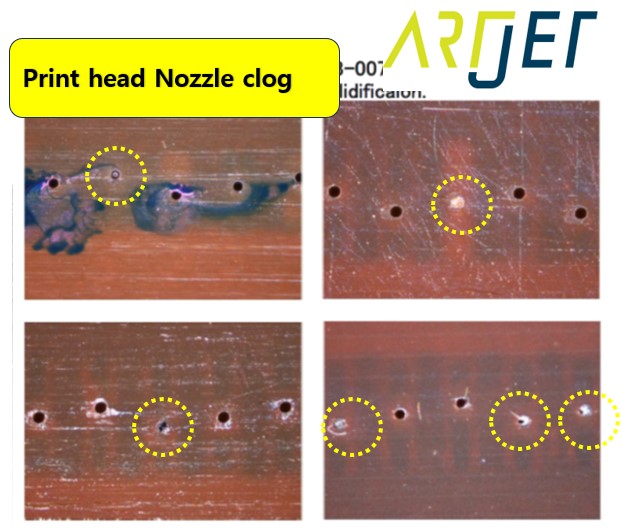

Tiny ink droplets flying around not only land on the substrate, but also adhere to the print head nozzle surface.

- When one or two small droplets gather, they form a large droplet.

- This large droplet partially blocks the nozzle orifice, preventing the ink from being sprayed straight.

- This creates a diagonal spray pattern, which appears as a banding pattern and affects print quality.

A bigger problem is that

- if this partially deposited ink on the print head nozzle surface is not properly wiped away,

- the ink remaining around the nozzle hardens due to the lamp, and may not recover even after cleaning.

- Initially, the diagonal spray pattern affects print quality. As ink accumulates and hardens, it eventually clogs the nozzle.

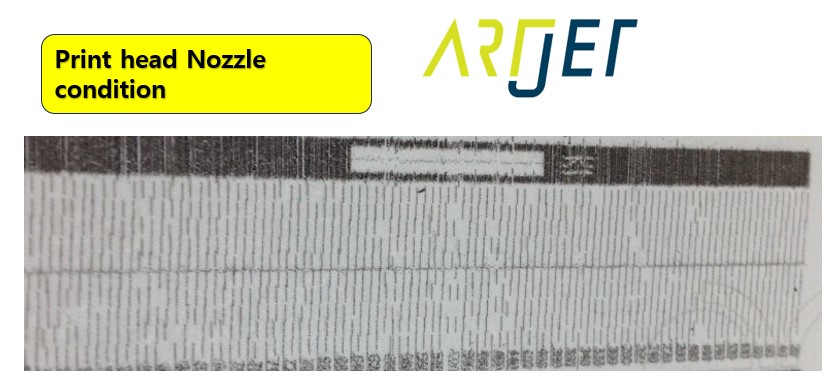

See the photos below for partial and complete nozzle clogging.

In this state, the print head nozzle pattern photo is as follows.

3. Customer _iPhone 14 Printing Limits ARTJET 2025

Despite these risks, some people occasionally print iPhone 14 cases with ARTJET.

At first, they used a zigzag to print multiple cases, but the air turbulence caused the starting point for each case to be slightly off. Now, they print one case at a time.

Even now, when I occasionally talk to the company representative,

“Sir, if possible, please look for something other than the iPhone 14 case.”

I’ve also heard from some representatives that they purchase cases that can be reassembled by removing the iPhone 14 camera.

After speaking with several company representatives, I’ve heard that while the print quality is lower, it’s possible to print iPhone 14 cases with Mimaki.

IV. This is how ARTJET supports our customers.

One thing I feel while selling and maintaining ARTJET UV Printers for 5 years is that the next most important thing after product stability is Troubleshooting DATA.

All products have problems, whether they are actual equipment problems or consumer errors, and product stability is how easily and quickly you solve those problems.

We are organizing all the troubleshooting DATA as follows.

You can see the product print quality by clicking here.

1. Additional information on printhead problems

Please refer to the information summarized above, and there is no additional information summarized yet.

2. Additional information on ink supply issues

Please refer to the information summarized above, and the additional information summarized below is as follows.

Addition

“no clogged nozzles, but banding in the red ARTJET 2025”

“When I print it, the whole thing has a yellow tint to it”

3. Additional information on Mechanical issues

Please refer to the information summarized above, and there is no additional information summarized yet.

4. Additional information on Electron board and Software issues

Please refer to the information summarized above, and there is no additional information summarized yet.

5. Additional information on Sai Flexi Rip software

Please refer to the information summarized above, and there is no additional information summarized yet.

6. Problems and solutions from actual consumer sites

1. Paper that absorbs ink

2. A line-like thing appears at the end of the white print surface

3.Can varnish banding be reduced?

4. Are there many problems with China’s UV Printer?

7. UV Printer Application

we are explaining not only UV printer problems and solutions, but also what products are produced with UV printers.

1. Braille printing

2. Flip the material and align it

3. 2.5D UV print

4. ARTJET UV Printer Application 6 _아크릴 본딩 장비

5. I phone 14 print limitation

6. Mask printing not recommend

7. Leather Cigarette Case UV Printing

8. Round soccer strategy board UV printing

9. Primer performance & limitation

10. UV Print & Laser crop mark cutting

11. Mobil case UV print profit

12. Screen vs Digital Comparison and UV Printing on Hand Sanitizer Cases

13. Bottle zig & print

14. Canvas UV Printing

15. Applying epoxy effect with varnish

16. Making a light frame with UV Printer & Laser cutter

17. UV Printer & Laser Cutting Equipment Button Name Tag Making

18. UV Printer & Laser Cutting Making a Cell Phone GripTok

19. Making an Acrylic Keychain with UV Printer & Laser Cutter

20. UV Print with Zig

21. How to make RD WORKS CCD camera cutting Video manual

22. Acrylic bonding equipment

23. All the steps to create UVDTF

24. UVDTF TEST Result on various material

25. ARTJET CW+C Print time & Ink Cost

26. Create a white shield with different images on the front and back of the keyring

27. Keyring Business Required Equipment and Investment Costs

29. Acrylic Lighting Goods

30. Ballpoint pen jig printing

31. Staining occurs when printing on coated leather

8. Bonus

1. ARTJET UV Printer Old Model Refurbished

2. UV Printer Laser Cutter Bonding Machine Which equipment should I buy first?

3. Considerations when choosing a UV printer

4. DTF Printer Price and Specification Survey

5. Acrylic Bonding Equipment Don’t Put It Off Anymore

6. China inkjet level now

7. Thoughts on KOSIGN 2024

8. ARTJET Delivery Preparation

9. ARTJET Setting Sequence

10. UV Printer History and Future Prediction 1

11. UV Printer History and Future Prediction 2

12. UV Printer History and Future Prediction 3

13. UV Printer History and Future Prediction 4

14. UV Printer History and Future Prediction 5

15. Are there many problems with China’s UV Printer?

16. UV Printer Small Text Meaning

17. Is the XP600 head okay

18. Roland UV Printer Summary

19. Mimaki UV Printer Summary

20. UV Printer Alibaba Direct Purchase Considerations

21. Things to consider when buying a used UV Printer

22. Bi Uni Print Quality Differences

23. RDworks download install and laser head position by SW

That’s it for today.

핑백: Primer functionality and limitations ARTJET 2025