Slanted material UV printing

So far, UV printer-related issues, We’ve compiled

24 articles on ink supply issues,

9 articles on head basics,

12 articles on actual head issues and their solutions,

10 actual mechanical Machine Problems and Solutions.

12 Problems and Solutions of Electronic Boards and SW Actually Issued

11 Problems and Solutions: Sai Rip Installation and Basic Settings, Spot Color Creation, and More

For related information, click on the article to go to the link.

Now, I’m explaining about the products that can be made with a UV Printer

Expressing gradients and three-dimensionality with white

4. “It is not easy to print a phone case because of the height of the iPhone 14 camera.”

5. “Do not print masks with a UV printer.”

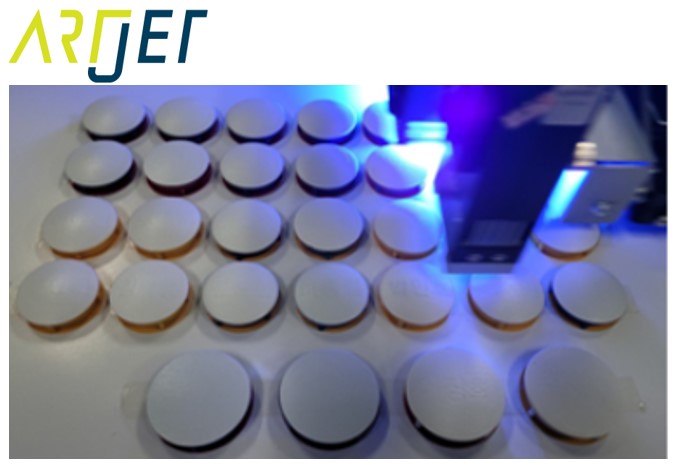

Today I’m going to show you how to print names on slanted material used on soccer tactical boards.

I. Material condition to be printed _Slanted material UV printing

1. Messy name tags with adhesive sheets _Slanted material UV printing

This project involved marking player names on magnets used in soccer strategy boards.

Previously, we used adhesive sheets to mark the names, but over time, the adhesive began to peel off, so we requested UV printing.

The adhesive sheets didn’t come off easily, so we gave up on printing on the areas that didn’t come off.

Where the adhesive sheet remained, no matter how thick the white ink was, a messy, uneven surface appeared.

If any adhesive sheet remains on the printing surface, it must be thoroughly removed to ensure a clean finish after UV printing.

2. Strong background colors are not easily masked with white alone _Slanted material UV printing

This task requires reprinting the player roster on the name tags that still have the names.

The names in red and black are difficult to completely mask, no matter how thickly I apply the white ink.

Strongly colored inks must be stripped to mask the white ink.

Although I stripped the black and red ink, they remained a bit dirty, so I printed the white ink twice.

II. To print on an inclined surface _Slanted material UV printing

1. Print mode _Slanted material UV printing

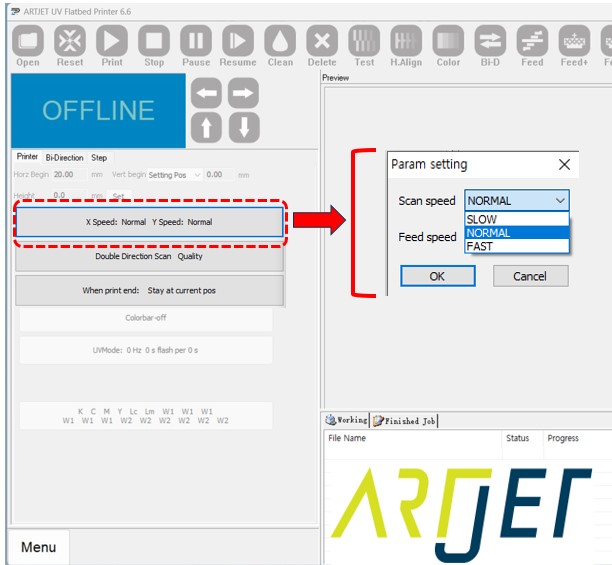

Since the material output has some curvature, I adjusted the print mode in the printer program accordingly.

* Single-leave (unidirectional printing)

* Scan Speed ”SLOW” and feed speed “SLOW”

Please refer to the window below for adjusting the head carriage speed (scan speed) and Y-axis platen feed speed (feed speed).

2. Why I chose Slow _Slanted material UV printing

The printer program has three modes for the head carriage speed: FAST, NORMAL, and SLOW.

- In FAST mode, the head carriage moves at approximately 1,000 mm per second.

- In NORMAL mode, it moves at approximately 800 mm per second,

- and in SLOW mode, it moves at approximately 400 mm per second.

The faster the head carriage speed, the more the ink falling downward is affected by the inertia of the head carriage moving side-to-side.

In particular, the further away the ink impact point is, the slower the ink falls, making it more susceptible to the side-to-side movement of the head carriage.

In other words, the faster the head carriage speed, the further away the ink impact point is, and the less likely the ink is to fall into its proper position.

For this reason, when printing on rounded materials, where the ink impact point is further away on an inclined surface,

the head carriage should move at a slower speed to reduce the inertia and ensure the ink falls into its proper position.

For this reason, the head carriage transfer speed was selected as the slowest, Slow.

3. Additional information about the settings window _Slanted material UV printing

The head carriage speed (scan speed) and the Y-axis platen feed speed must be the same.

The head carriage moves quickly for printing, but if the platen feed speed is slow, the head carriage will have no choice but to stop until the Y-axis feed is complete.

If this error accumulates, the printer logic will become erratic, causing printing to stop.

In other words, when adjusting the head carriage speed, the Y-axis feed speed must also be adjusted.

- If the scan speed is FAST, the feed speed is FAST.

- If the scan speed is NORMAL, the feed speed is NORMAL.

- If the scan speed is SLOW, the feed speed is SLOW.

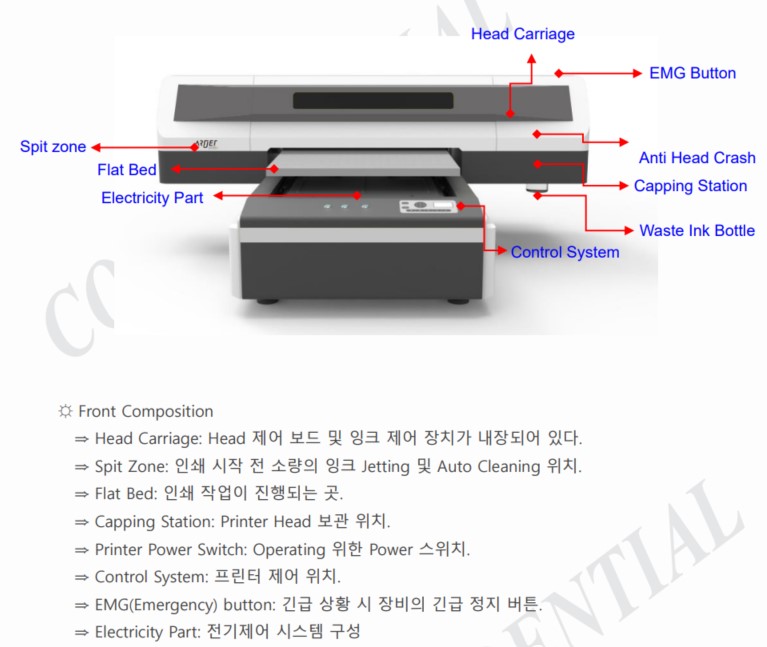

For those unfamiliar with the head carriage, see below.

Although it’s not visible due to the cover, the large unit that moves back and forth during printing is called the head carriage.

The feed speed refers to the slight forward or backward movement of the platen with each print.

4. Results _Slanted material UV printing

Since I selected Slow for the carriage speed, the overall printing time was bound to be longer.

Furthermore, because the material is curved, I selected unidirectional printing mode, which slowed down the printing process even more than bidirectional printing.

Because of the messy printed surface, I printed the white part twice, which also doubled the printing time.

This is the result, and the name was printed on the rounded surface without any problems.

III. This is how ARTJET supports our customers.

One thing I feel while selling and maintaining ARTJET UV Printers for 5 years is that the next most important thing after product stability is Troubleshooting DATA.

All products have problems, whether they are actual equipment problems or consumer errors, and product stability is how easily and quickly you solve those problems.

We are organizing all the troubleshooting DATA as follows.

You can see the product print quality by clicking here.

1. Additional information on printhead problems

Please refer to the information summarized above, and there is no additional information summarized yet.

2. Additional information on ink supply issues

Please refer to the information summarized above, and the additional information summarized below is as follows.

Addition

“no clogged nozzles, but banding in the red ARTJET 2025”

“When I print it, the whole thing has a yellow tint to it”

3. Additional information on Mechanical issues

Please refer to the information summarized above, and there is no additional information summarized yet.

4. Additional information on Electron board and Software issues

Please refer to the information summarized above, and there is no additional information summarized yet.

5. Additional information on Sai Flexi Rip software

Please refer to the information summarized above, and there is no additional information summarized yet.

6. Problems and solutions from actual consumer sites

1. Paper that absorbs ink

2. A line-like thing appears at the end of the white print surface

3.Can varnish banding be reduced?

4. Are there many problems with China’s UV Printer?

7. UV Printer Application

we are explaining not only UV printer problems and solutions, but also what products are produced with UV printers.

1. Braille printing

2. Flip the material and align it

3. 2.5D UV print

4. ARTJET UV Printer Application 6 _아크릴 본딩 장비

5. I phone 14 print limitation

6. Mask printing not recommend

7. Leather Cigarette Case UV Printing

8. Round soccer strategy board UV printing

9. Primer performance & limitation

10. UV Print & Laser crop mark cutting

11. Mobil case UV print profit

12. Screen vs Digital Comparison and UV Printing on Hand Sanitizer Cases

13. Bottle zig & print

14. Canvas UV Printing

15. Applying epoxy effect with varnish

16. Making a light frame with UV Printer & Laser cutter

17. UV Printer & Laser Cutting Equipment Button Name Tag Making

18. UV Printer & Laser Cutting Making a Cell Phone GripTok

19. Making an Acrylic Keychain with UV Printer & Laser Cutter

20. UV Print with Zig

21. How to make RD WORKS CCD camera cutting Video manual

22. Acrylic bonding equipment

23. All the steps to create UVDTF

24. UVDTF TEST Result on various material

25. ARTJET CW+C Print time & Ink Cost

26. Create a white shield with different images on the front and back of the keyring

27. Keyring Business Required Equipment and Investment Costs

29. Acrylic Lighting Goods

30. Ballpoint pen jig printing

31. Staining occurs when printing on coated leather

8. Bonus

1. ARTJET UV Printer Old Model Refurbished

2. UV Printer Laser Cutter Bonding Machine Which equipment should I buy first?

3. Considerations when choosing a UV printer

4. DTF Printer Price and Specification Survey

5. Acrylic Bonding Equipment Don’t Put It Off Anymore

6. China inkjet level now

7. Thoughts on KOSIGN 2024

8. ARTJET Delivery Preparation

9. ARTJET Setting Sequence

10. UV Printer History and Future Prediction 1

11. UV Printer History and Future Prediction 2

12. UV Printer History and Future Prediction 3

13. UV Printer History and Future Prediction 4

14. UV Printer History and Future Prediction 5

15. Are there many problems with China’s UV Printer?

16. UV Printer Small Text Meaning

17. Is the XP600 head okay

18. Roland UV Printer Summary

19. Mimaki UV Printer Summary

20. UV Printer Alibaba Direct Purchase Considerations

21. Things to consider when buying a used UV Printer

22. Bi Uni Print Quality Differences

23. RDworks download install and laser head position by SW

That’s it for today.