ARTJET UV Printer troubleshooting Bi direction printing 1

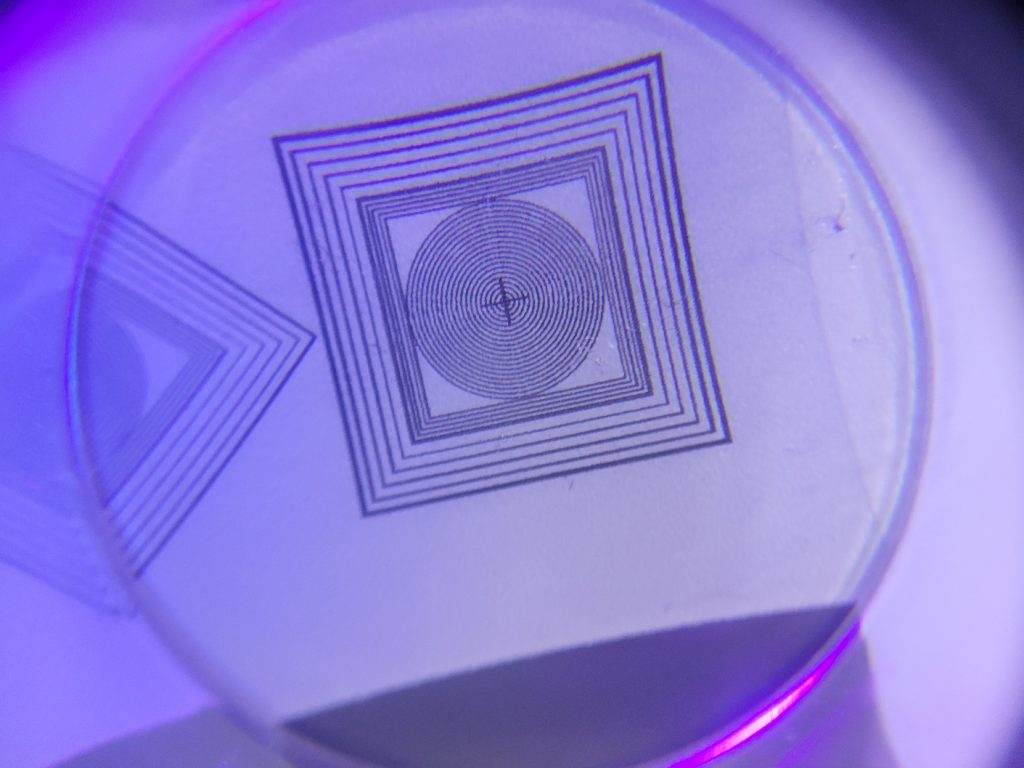

The photo below shows small text viewed through a 10x magnifying glass, and was printed in bi directions.

In order to print such small text well in bi directions, several conditions must be met.

Today we will look at the basic concepts and conditions of bi direction printing.

What is Bi direction Printing?

Bi direction printing basic concept

– Everyone who uses a wide format (1.2 x 2.5 meter flat bed or larger) UV printer knows this.

– Occasionally, among those who use small flat bed (less than 0.6 x 0.9 meter flat bed), there are representatives who do not know, so we will only explain the basic concepts.

– When viewed from the front, the print head carriage moves slowly when moving from right to left, but when moving in the opposite direction, it moves quickly and prints.

– In most cases, when moving slowly, ink is jetted and printing is on going, and when moving quickly, it does not print and just returns.

– In other words, printing proceeds in only one direction. Printing in one direction like this is called “uni directional printing.”

– Printing as the print head carriage moves and returns while maintaining the same speed is called “bi-directional printing.”

Uni & Bi direction printing output speed difference

– The reason people who have wide format UV printers always want to print in bi directions is for productivity.

– Just thinking about it, wouldn’t the one-way comparison production line go up twice as much since it is printed both when leaving and when returning? You may think so, but it is correct to say that productivity increases by approximately 70-80%.

– In unidirectional printing, when not printing, the print head carriage moves quickly and returns,

– In the case of bi-directional output, the same speed is maintained both times, so productivity does not double.

Uni & Bi direction printing output quality difference

– Most people who use wide format UV printers have their own standards, such as unidirectional printing and bidirectional printing, just by looking at the image file to be printed.

– Images containing a lot of solid colors may not be expressed properly when printed in bi directions.

– When images containing small text are printed in bi directions, small text may not be displayed well in certain areas of the entire flat bed.

– Also, for images containing a human face or a lot of skin, when printing bidirectionally, the face looks rough or it is not easy to obtain the desired color, so even if productivity is reduced, unidirectional printing is chosen.

– In this way, compared to unidirectional output, bidirectional output is not easy to express small letters, skin tones may look rough, and unknown banding is more visible when printing in solid color.

Bi direction output conditions

– In order to achieve this quality with bidirectional output, several conditions are necessary.

– This is a 10x enlarged photo, and the first image is what super experts see (note that the head must be new, and flatbed is also not available like this in all segments),

– And the second image is the image seen by experts (this is the level of quality that can be obtained without any deviation in all sections of flatbed).

Ink jetting conditions

– The photo below shows ink jetting while the print head is fixed in place and was taken with a high-speed camera.

– As shown in the photo, when all ink comes out of the print head nozzle, conditions must be met to come out in a straight direction, not diagonally.

– If the ink is not made properly or the print head waveform is not tuned properly, the ink may come out diagonally instead of straight, or some nozzles may not jet ink at all.

Print head nozzle condition

– In the case of the print head, it is in the best condition when newly installed.

– However, as time passes, diagonal jetting may occur for various reasons, and as it ages, the straightness may decrease.

– When using in bi directions printing, you must judge whether the nozzle condition is good or bad.

Offset function in software program

– Mechanically, the print head must be vertical,

– CMYK Lc Lm, White, and Varnish must all be offset adjusted from left to right and right to left for each channel.

– In addition, the offset must be adjusted not only in the left and right directions, but also in the vertical direction to implement a circle without distortion and 2 font text as shown in the photo above.

– And lastly, the bi direction offset adjustment function must be have based on the each print head carriage speed.

– This condition must be included in the software program to obtain the desired bi direction printing quality.

Head height can be set in 0.1 mm increments

– Commonly, it is called stand off. In other words, it refers to the gap between the material and the head. As you can see in the link below, the optimal stand off is specified for each head manufacturer.

– During printing, the print head carriage moves at a speed of approximately 800 mm per second, or up to 1,000 mm per second.

– The condition for maintaining the straightness of the ink coming out of the print head nozzle uniformly despite this movement is a 1.2 mm gap.

– If the head height adjustment on your UV printer is not adjusted in 0.1 mm increments through software program, but must be adjusted visually, and the displayed height is displayed in 1 mm increments rather than 0.1 mm increments, because the head height is bound to change from time to time, bi direction printing is not easy.

The limits of flatbed flatness

– When printing in bi direction, if the flatbed flatness differs by more than 0.2 to 0.3 mm, clear 2-font text cannot be obtained in some sections when printing in bi direction.

– As the print head carriage moves from left to right at a speed of 800 to 1000 mm per second, the falling ink droplets receive the force of inertia and jet the ink slightly to the right rather than exactly vertically.

– Conversely, when printing as the carriage moves from right to left, ink is jetted slightly to the right.

– In this state, if the flatbed flatness itself differs by 0.2 to 0.3 mm, that part will be out of focus.

– Unless a surface plate is used, all flat flatness can have this level of error rate, and for this reason, when setting up the equipment, the flatbed flatness is adjusted so that the error rate is as small as possible.

For bi-directional printing, the UV printer itself must have at least

– You must use ink that matches the print head.

– The print head must be mechanically aligned,

– There must be separate left and right offsets for all color, white, and varnish channels, and in this case, there must be separate offsets in bi directions.

– For a circle without distortion and a clean 2 font text quality like in the above photo, there must be an upper and lower offset.

– Head height adjustment must be possible in 0.1 mm increments through the software program, rather than visually adjusting it by pressing buttons.

– The flatbed flatness must be as smooth as possible.