ARTJET UV Printer Application 17 _ bottle print

ARTJET UV Printer has been sold in Korea for 4 years, and we are organizing the printer problems we have encountered so far, their causes, and their solutions.

We have compiled 10 different print head problems and 17 ink supply problems, and you can find detailed information at the site below.

ARTJET UV Printer troubleshooting sum up

From last time, we are explaining not only UV printer problems and solutions, but also what products are produced with UV printers.

In the first session, ARTJET UV Printer Application 1 braille printing

In the second session, ARTJET UV Printer Application 2 Flip the material and align it

In the third session, ARTJET UV Printer Application 3 2.5D UV print

In the fourth session, Sai rip [Color Adjustment] tab. ARTJET UV Printer Application 4 Sai rip color graph

In the fifth session, ARTJET UV Printer Application 5 Sai rip print size compensation

In the sixth session, we talked about the acrylic bonding equipment that those who have UV printers and laser cutting equipment are looking for.

Hereuner is only Korean since only Korea is hot on this machine. ARTJET UV Printer Application 6 _아크릴 본딩 장비

In the seventh session ARTJET UV Printer Application 7 _ Ink Consumption Calculation

In the Eighth session, ARTJET UV Printer Application 8 _ I phone 14 print limitation

About K print, Korea Signage Label & special printing exhibition, ARTJET UV Printer Market research 1 _ K Print 2024 Korea printing exhibition

In the ninth session, ARTJET UV Printer Application 9 _ Mask printing not recommend

In the tenth session, ARTJET UV Printer Application 10 _ Leather Cigarette Case UV Printing

In the eleventh session, ARTJET UV Printer Application 11 _ Round soccer strategy board UV printing

In the twelve session, ARTJET UV Printer Application 12 _ What is ICC profile & menu board UV Printing

In the thirteen session, ARTJET UV Printer Application 13 _ Primer performance & limitation

In the fourteen session, ARTJET UV Printer Application 14 _ UV Print & Laser crop mark cutting

In the fifteen session, ARTJET UV Printer Application 15 _ Mobil case UV print profit

In the sixteen session, ARTJET UV Printer Application 16 _ Screen vs Digital Comparison and UV Printing on Hand Sanitizer Cases

Today I will explain the bottle printing

I. 5 Ways to Print a Bottle

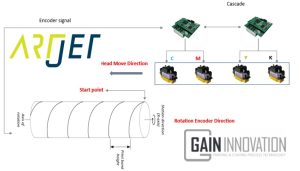

1. Printing by linking bottle jig motion to UV Printer Y-axis

If you watch the YouTube video below, it explains everything from installation to actual printing in detail. I strongly recommend that you refer to it to understand my writing.

https://www.youtube.com/watch?v=A0BgH7q7jYo

This is a way to print by connecting power and signals so that the bottle can move on the Y-axis motion.

It is a solid and well-made bottle jig.

It is a bottle jig that is actually available at ARTJET, but I do not recommend it to buyers.

“Why I don’t recommend it?” I will explain later.

2. Method of rotating the bottle jig using rubber on the UV Printer Y-axis flatbed

This is a method of attaching rubber to a circular frame and moving the bottle jig by friction of the rubber as the Y-axis moves.

It is less stable than directly linking to the motion, but it is still useful.

For detailed video, please refer to the YouTube below..

https://www.youtube.com/watch?v=MqwZ7D_96e8

Although it is inexpensive, printing stability needs to be checked as it feeds whenever the flatbed moves rather than along the Y-axis motion.

3. Printer dedicated to the bottle

It’s an American company called InkCups.

It’s for bottle printers only, and as you can see from the video below, it seems to have solved the image distortion problem.

It’s priced between 100 million and 150 million won.

https://www.youtube.com/watch?v=32W_X_L0yRo

4. Factory-use bottle printer

It’s a mass production bottle printer. I looked into the price a while ago and it’s said to be around 2 to 3 billion won.

https://www.youtube.com/watch?v=z0_Gg9VgoTY&list=PLHOhT7z9aJKWy-z3f-hxQoSsgzyj-RmRe

5. Tried but vulnerable to nozzle failure

This printing method is advantageous in terms of speed because it prints in a diagonal manner, but is vulnerable to print head nozzle failure.

https://www.youtube.com/watch?v=Xw6u07KVM9g

II. “Why don’t you recommend the bottle jig?”

1. A realistic bottle printer for us

The factory-type bottle printer and spiral bottle printer described above are not related to those who use UV Printers.

And, the method of printing while the bottle rotates quickly, in the case of No. 3 described above, it is a dedicated equipment that can only print bottles.

In the case of the bottle-only equipment, it is produced in China, but considering stability, we recommend American equipment.

If you want to print on a tumbler with different pi for the large and small diameters, you will need a separate image editing software. If you are considering purchasing Chinese equipment because of its low price, this is something you should definitely check.

For those of you who are using or planning to buy a UV Printer, the realistic alternative is No.1 No.2 Bottle Jig.

Although it is a realistic alternative, I will explain why I do not recommend Bottle Jig.

2. Decrease in productivity

The article below explains in detail why material and printhead spacing are important.

ARTJET UV Printer Application 8 _ I phone 14 print limitation

When the print head is used 100% to print the bottle,

the gap between the top of the bottle and the print head (let’s call it the stand off) is 1.2mm,

but as it goes beyond the top of the bottle, the stand off gradually increases by more than 1.2mm.

If the start and end points of the XP600 nozzle are approximately 2.56cm and the top of the bottle is 0.64cm,

the stand off in the section of 2.56-0.64 = 1.92cm is more than 1.2mm, and the stand off increases as it goes further away.

The photos below show the image quality when the print head is used at 50%, 30%, and 25% at the same height.

In this way, when using the bottle jig, only 25% of the print head is used, so the printing speed also decreases to 25%.

3. Adhesion and printing margin

UV Printers are mostly used in the field of goods and sign advertisements.

Most of the materials have been verified for adhesion, and for materials that have not been verified, a primer is applied to secure adhesion.

In the case of goods, there are cases where they are not touched by human hands, and in cases where they are touched by human hands, if the printed ink lasts for about 3 to 6 months, the product can be sold.

In the case of sign advertisements, since they are not touched by human hands much, there is no major problem even if you apply a primer on a sheet of iron or glass and print and deliver it.

However, when printing on a metal tumbler or glass cup, since it is washed and touched by human hands a lot, the adhesion must be better than that of sign advertisement products.

In this way, adhesion issues may arise when printing on expensive products such as metal and glass,

and since plastic bottles with good adhesion are inexpensive, the printing margin cannot be set high.

So, from a business perspective, it is difficult to print on materials with high margins. Also, materials that are easy to print on have low margins and are not profitable.

4. Cone image?

The Rip software and UV printer software you currently have do not have the function to make the image into a cone shape so that simultaneous printing is possible in areas with different pi.

The distances that the large and small diameters move in the glass cup are different each time they are fed.

The image is a right angle, but the material to be printed is a cone shape, so if you align the image in an area with a large pi, the image in an area with a small pi will be distorted, and vice versa.

In other words, printing is possible only for images with a small width.

5. However, for those who still need a bottle printer,

There are limitations, but UV DTF film seems to be a solution to some extent,

and for those with large production volumes, No.3 bottle-specific printer seems to be the answer.

Since it has been on the market for a long time, it seems to have a solution for conical images,

and I guess it also has a primer solution for existing customers.

That’s all for today.